Understanding PPH Butterfly Valves: Essential Insights for Industrial Applications

2025-08

One of the key attributes of PPH butterfly valves is their lightweight nature. This characteristic makes installation and maintenance significantly easier. Unlike heavier metal valves, PPH butterfly valves can be handled with minimal effort, reducing labor costs and improving efficiency during assembly or replacement. Furthermore, their corrosion resistance enhances their longevity, ensuring that they remain functional over time, even in harsh environments.

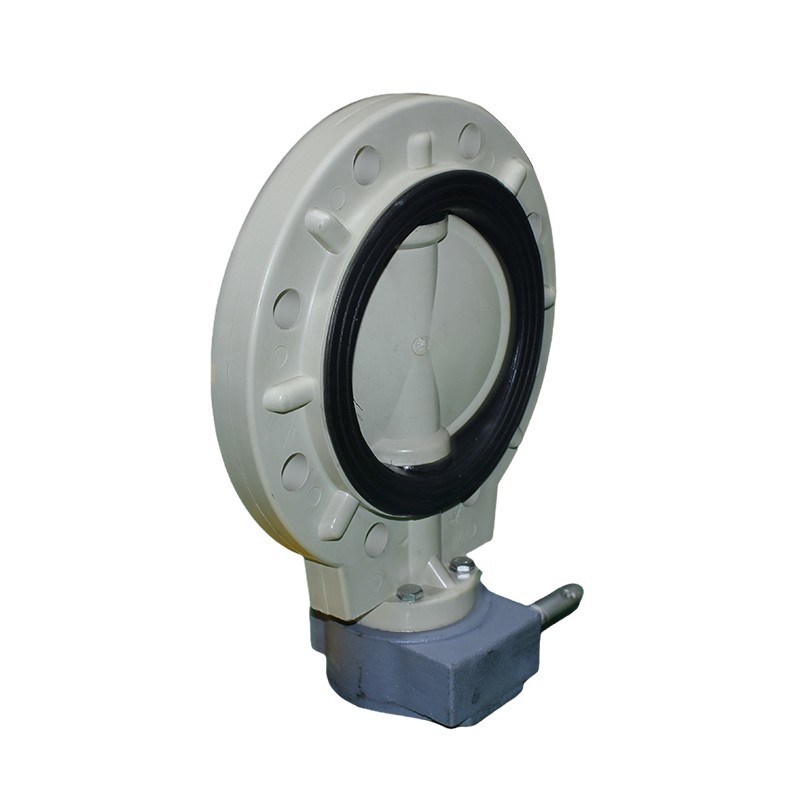

PPH butterfly valves feature a simple yet effective design, comprising a disc that rotates within the valve body to control flow. This mechanism allows for quick opening and closing action, providing precise flow control. Operators appreciate the ability to modulate flow rates with ease, making PPH butterfly valves ideal for applications where precise flow management is critical.

In addition to their basic functionality, PPH butterfly valves offer a range of benefits that enhance their usability. They are compatible with various piping configurations and can be easily integrated into existing systems. This versatility makes them suitable for a wide variety of applications, from regulating water flow in municipal systems to controlling the flow of chemicals in industrial processes.

Moreover, the ease of operation associated with PPH butterfly valves is supported by their low torque requirements. This means that less force is needed to open or close the valve, which can lead to reduced wear on the actuator and prolong the lifespan of the valve itself. This feature is particularly beneficial in automated systems where valves are operated frequently.

Another important consideration is the environmental impact. PPH butterfly valves are often designed with sustainability in mind, contributing to eco-friendly practices in industrial operations. Their durability and efficiency align with efforts to reduce waste and promote responsible resource management.

In conclusion, PPH butterfly valves are an essential component in industrial applications, offering a combination of lightweight construction, corrosion resistance, and efficient flow control. Their versatility and ease of use make them suitable for a wide range of industries, ensuring reliable performance in various environments. Understanding these attributes can help professionals make informed decisions when selecting valves for their operational needs.

RELATED INFORMATION

Understanding the Essential Role of Chemical Pipes in Modern Construction

Understanding the Essential Role of Chemical Pipes in Modern Construction Table of Contents Introduction to Chemical Pipes in Construction Types of Chemical Pipes Used in Construction Material Choices for Chemical Piping Systems Applications of Chemical Pipes in Various Industries Safety Standards and Regulations for Chemical Pipes Installation Techniques for Chemical Pipi

Understanding PPH Butterfly Valves: Essential Insights for Industrial Applications

In the realm of industrial equipment and components, the butterfly valve plays a pivotal role in regulating flow within piping systems. Among the different materials available for butterfly valves, PPH (Polypropylene Homopolymer) butterfly valves stand out due to their specific properties and advantages. Constructed from polypropylene, these valves offer excellent resistance to corrosive substance